Professional O-Ring and Oil Seal Manufacturer, Sealing Solution Supplier Since 2008.

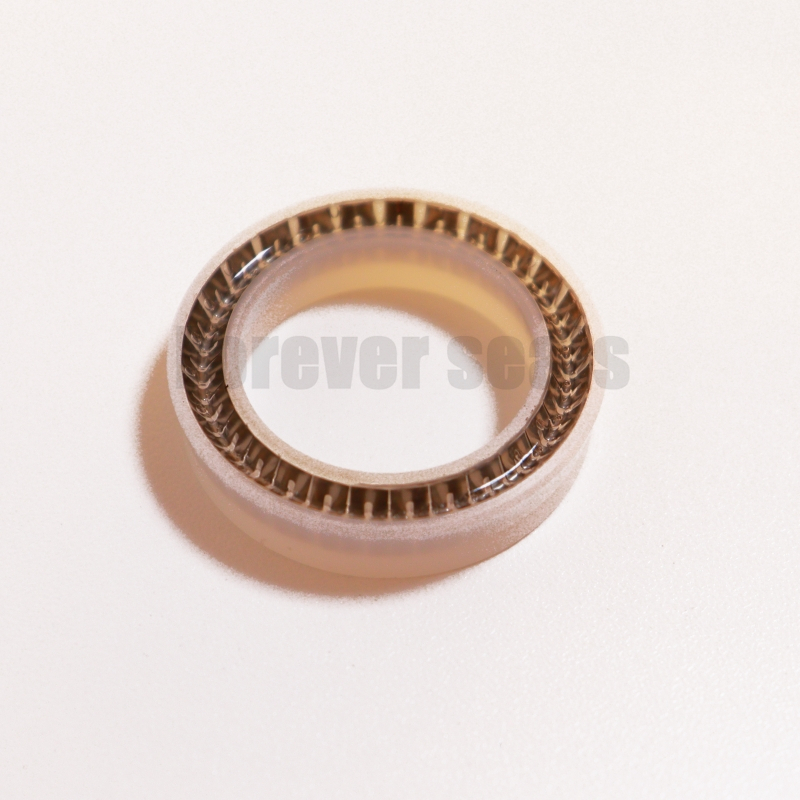

Transparent White UPE Material PTFE Spring Energized Seal

Embedded Stainless Steel Spring Ensures Reliable Sealing in Normal & Vacuum Environments

The Transparent White UPE Spring Energized Seal is a high-reliability precision sealing component. It features a transparent white ultra-high molecular weight polyethylene (UPE) body—boasting superior wear resistance, self-lubrication, and corrosion resistance—paired with an embedded stainless steel spring.

The spring delivers steady initial preload for tight sealing in normal pressure and vacuum, while UPE’s low-temperature durability (functional at liquid nitrogen temperatures) and non-toxic, hygienic traits meet strict safety needs.

Ideal for food, medical, chemical, and aerospace sectors, it prevents leakage, cuts friction-related energy loss, and ensures long-term performance in harsh or variable conditions.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

More Choices

no data

1. Product Advantages

Crafted by Forever Seals, this seal leverages UPE (Ultra-High Molecular Weight Polyethylene) for unmatched performance: top-tier wear resistance (8x that of plain carbon steel), inherent self-lubrication to reduce friction, and strong corrosion resistance against harsh media. It’s non-toxic, hygienic (meets food/medical safety standards), and retains ductility at liquid nitrogen temperatures—ensuring durability in extreme conditions.

2. Working Principle

The seal combines a UPE body with an embedded stainless steel spring. The spring provides initial preload for tight contact in normal pressure and vacuum environments; as system pressure rises, the UPE cavity’s pressure pushes the seal lip closer to the surface, maintaining leak-proof sealing across pressure fluctuations.

3. Product Details

Material: Transparent white UPE (main body) + stainless steel (spring)

Key Traits: Low friction coefficient, no lubrication dependency, long service life

Design: Compact structure, easy to install in precision equipment

4. Application Range

Ideal for Forever Seals’ target sectors:

Food industry (beverage filling lines)

Medical sector (pharmaceutical pump/valve sealing)

Chemical field (corrosive medium pipelines)

Aerospace (hydraulic/pneumatic systems)

5. FAQ

Q: Is this seal suitable for vacuum environments?

A: Yes—its spring-driven preload ensures reliable sealing in vacuums.

Q: Can it be used in food contact applications?

A: Absolutely; UPE’s non-toxic, hygienic properties meet global food safety standards.

6. Company Selling Points (Forever Seals)

Expertise in precision sealing solutions tailored to industry needs

Strict quality control for consistent product performance

Fast customization support for unique equipment requirements

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get In Touch With Us

We are committed to meeting the diverse needs of our global customers through innovation and continuous improvement.

Need more information?

If you didn't find what you need, you can send an inquiry through our contact form.

Please fill in the form below.

Quick Links

Products

Contact Us