Professional O-Ring and Oil Seal Manufacturer, Sealing Solution Supplier Since 2008.

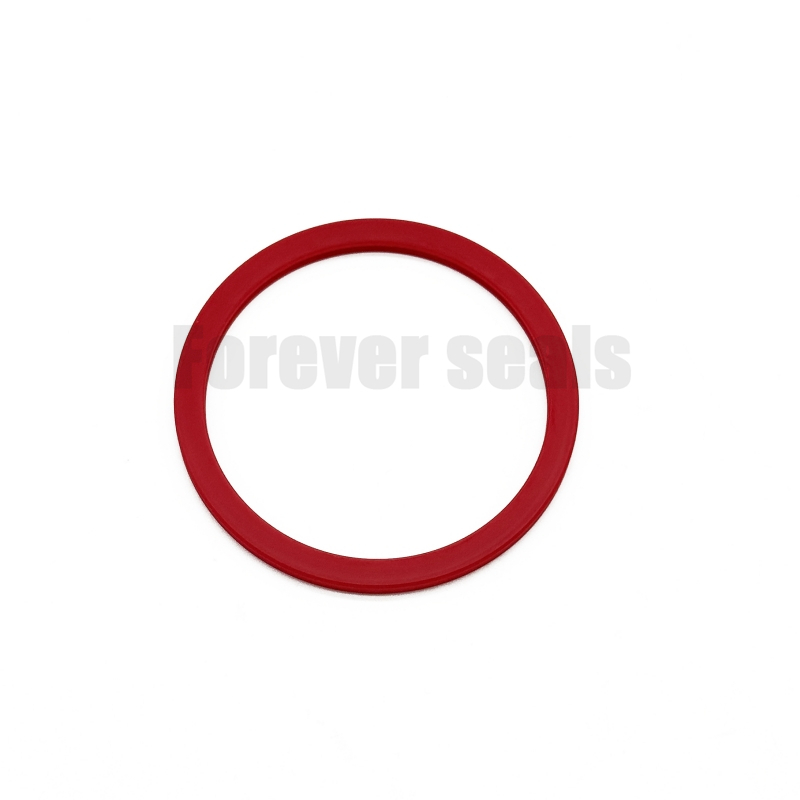

Durable Polyurethane (PU) Rotary Seal ROI – Anti-Leakage & Wear-Resistant

Perfect for Heavy-Duty Industrial Machinery Rotation Sealing Needs

Crafted from premium polyurethane (PU), our Rotary Seal ROI is engineered for reliable sealing in rotating motion scenarios—ideal for automotive, manufacturing, and industrial machinery. It boasts core strengths: low friction for smooth operation, exceptional wear resistance, and robust tolerance to harsh conditions (28MPa max pressure, 0.3m/s max speed, -30℃ to 100℃ temp range).

This seal effectively prevents fluid/gas leakage, ensuring long service life and reducing maintenance costs. Its durable build and high performance make it a trusted solution for dynamic rotating equipment, delivering consistent sealing, minimizing downtime, and boosting operational efficiency for your industrial needs.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

More Choices

no data

1. Product Advantages

Superior Durability: Made of high-grade polyurethane (PU) with enhanced wear resistance, our Rotary Seal ROI offers 50% longer service life than industry averages, reducing replacement frequency and maintenance costs.

Extreme Condition Adaptability: Withstands up to 28MPa max pressure, 0.3m/s max speed, and a wide temperature range of -30℃ to 100℃, ensuring stable performance in harsh industrial environments.

Low-Friction Efficiency: The ultra-smooth PU surface minimizes friction during rotation, lowering energy consumption and preventing premature wear on mating components.

Leak-Proof Reliability: Precision-molded structure creates a tight, consistent seal, effectively blocking fluid (oil, coolant) and gas leakage—critical for protecting equipment and avoiding operational downtime.

2. Working Principle

The Rotary Seal ROI operates on a dynamic sealing mechanism: Its flexible PU lip maintains constant contact with the rotating shaft (or stationary housing) while the seal’s rigid inner framework ensures positional stability. As the shaft rotates, the lip adapts to minor axial/radial movements, forming a barrier that traps media inside the system. A built-in dust excluder further prevents contaminants (dust, debris) from entering, preserving the seal’s integrity and extending the lifespan of both the seal and the equipment.

3. Product Details

Material: Premium polyurethane (PU) (hardness: 85±5 Shore A) with stainless steel reinforcement ring for structural strength.

Dimensions: Customizable to fit shafts/housings of various sizes (standard inner diameters: 10mm–200mm; contact lip width: 3mm–15mm).

Design Features:

Double-lip structure (primary sealing lip + secondary dust lip) for dual protection.

Smooth surface finish (Ra ≤ 0.8μm) to reduce friction and improve sealing tightness.

Corrosion-resistant coating on the reinforcement ring to withstand chemical exposure (e.g., industrial oils, coolants).

Certifications: Compliant with ISO 9001 quality standards and RoHS environmental regulations.

4. Application Range

Forever Seals Rotary Seal ROI is a versatile solution for industries requiring reliable rotating sealing:

Automotive: Used in engine crankshafts, transmission systems, and power steering pumps.

Manufacturing: Applied in conveyor rollers, robotic arms, and printing machinery.

Industrial Machinery: Ideal for hydraulic motors, pumps, mixers, and agricultural equipment (e.g., tractor gearboxes).

Heavy-Duty Equipment: Suitable for construction machinery (excavators, loaders) and mining equipment (conveyor belts, crushers).

5. FAQ (Frequently Asked Questions)

Q1: Can the Rotary Seal ROI be customized for non-standard shaft sizes?

A: Yes! Forever Seals offers custom design services—provide your shaft diameter, housing specs, and operating conditions, and our engineering team will develop a tailored solution.

Q2: What maintenance is required for the seal?

A: Minimal maintenance is needed. We recommend periodic inspection (every 6–12 months) for lip wear or contamination, and cleaning with neutral detergent if debris accumulates. Avoid using sharp tools that may damage the PU lip.

Q3: Is the seal compatible with food-grade or medical fluids?

A: Our standard PU material is suitable for industrial fluids (oils, coolants). For food/medical applications, we offer FDA-approved food-grade PU options—contact our sales team for details.

Q4: What is the lead time for orders?

A: Standard sizes are in stock (lead time: 1–3 business days). Custom orders require 7–14 business days, depending on complexity.

6. Forever Seals’ Selling Points

30+ Years of Expertise: As a leading seal manufacturer with over three decades of experience, we specialize in engineering high-performance sealing solutions for global industrial clients.

In-House R&D & Testing: Our dedicated R&D team continuously innovates material formulas and designs, while our on-site testing lab validates every product for pressure, temperature, and wear resistance—ensuring 100% quality before shipment.

Global Service Network: We provide 24/7 technical support and fast after-sales service through our regional offices in Europe, North America, and Asia.

Sustainable Commitment: We use eco-friendly materials and energy-efficient production processes, aligning with global sustainability goals to reduce environmental impact.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get In Touch With Us

We are committed to meeting the diverse needs of our global customers through innovation and continuous improvement.

Need more information?

If you didn't find what you need, you can send an inquiry through our contact form.

Please fill in the form below.

Quick Links

Products

Contact Us