Professional O-Ring and Oil Seal Manufacturer, Sealing Solution Supplier Since 2008.

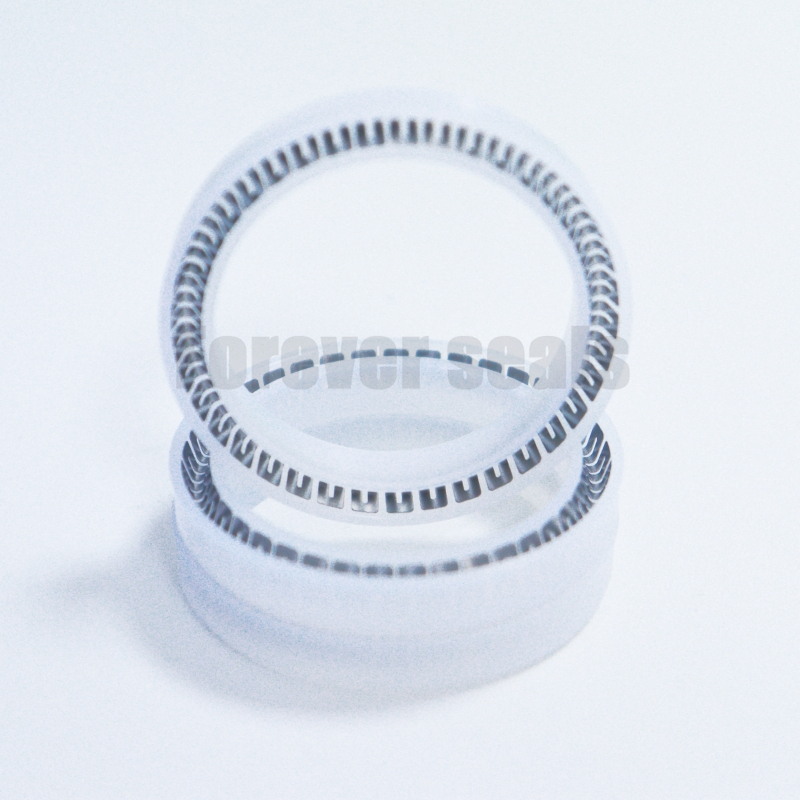

Clear White Ultra-High Molecular Weight Polyethylene (UPE) Spring Energized Seal

Durable Transparent White UPE Spring Energized Seal for Precision Sealing Applications

This spring energized seal stands out with its transparent white UPE (Ultra-High Molecular Weight Polyethylene) material, blending functional performance with visual clarity for industrial and precision sealing scenarios. Engineered to deliver consistent, reliable sealing, it leverages UPE’s inherent advantages—exceptional wear resistance, strong chemical stability, and low friction—ensuring long-term durability even in demanding operating conditions, such as exposure to corrosive media or repeated mechanical contact. The transparent white design adds practical value, allowing for easy visual inspection of seal alignment, wear status, or potential debris buildup without disassembly, simplifying maintenance and reducing downtime. Suitable for diverse applications ranging from hydraulic systems and pumps to precision machinery, this seal balances robustness and visibility, making it a high-performance choice for users seeking both effective sealing solutions and operational convenience.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

More Choices

no data

1. Product Advantages

Crafted with premium transparent white UPE (Ultra-High Molecular Weight Polyethylene), this spring energized seal from Forever Seals delivers unmatched performance for industrial sealing needs:

- Superior Durability: UPE’s inherent high wear resistance and impact strength ensure long service life, even under repeated mechanical contact or harsh operating conditions.

- Strong Chemical Stability: Resists corrosion from most oils, solvents, and mild chemicals, making it suitable for diverse fluid-handling scenarios.

- Visual Clarity: The transparent white design enables real-time visual inspection of seal alignment, wear, or debris buildup—no disassembly required, reducing maintenance time and downtime.

- Low Friction Operation: UPE’s smooth surface minimizes friction between the seal and mating components, preventing premature wear and ensuring consistent sealing performance.

2. Working Principle

This spring energized seal operates on a “spring-assist” mechanism to maintain reliable sealing contact:

- A high-performance metal spring (embedded within the UPE matrix) provides constant radial or axial force, ensuring the seal lip stays in tight contact with the mating surface—even when equipment experiences thermal expansion, pressure fluctuations, or minor dimensional variations.

- The transparent white UPE outer layer acts as the primary sealing element: its low friction coefficient reduces drag, while its chemical resistance protects the internal spring from corrosive media.

- Together, the UPE layer and embedded spring create a dynamic seal that adapts to operating changes, preventing fluid leakage and maintaining system integrity.

3. Product Details

| Specification | Details |

|---|---|

| Material | Outer layer: Transparent white UPE (Ultra-High Molecular Weight Polyethylene); Internal spring: Stainless steel (304/316 optional) |

| Color | Transparent white (clear visibility for inspection) |

| Hardness | 60-70 Shore D (optimized for flexibility and wear resistance) |

| Temperature Range | -20°C to 80°C (standard); Customizable for -40°C to 120°C for extreme environments |

| Pressure Range | Up to 30 MPa (suitable for low to medium-pressure industrial systems) |

| Standard Sizes | 5mm to 200mm inner diameter (custom sizes available for specific equipment) |

4. Application Range

Forever Seals’ Transparent White UPE Spring Energized Seal is engineered for versatility, ideal for:

- Hydraulic & Pneumatic Systems: Sealing cylinders, valves, and pumps in industrial machinery, construction equipment, and automotive hydraulic circuits.

- Precision Machinery: Semiconductor manufacturing equipment, medical devices, and laboratory instruments (where visual inspection and chemical resistance are critical).

- Fluid Handling Equipment: Food-grade processing systems (UPE is non-toxic and compliant with basic food contact standards) and chemical transfer pumps.

- General Industrial Use: Gearboxes, compressors, and rotating shafts requiring reliable, low-maintenance sealing.

5. FAQ

Q1: Can this seal withstand high-temperature environments?

A1: The standard model operates reliably between -20°C and 80°C. For high-temperature applications (up to 120°C), Forever Seals offers a modified version with heat-stabilized UPE and high-temperature-resistant springs—contact our team for customization.

Q2: Is the transparent white UPE material food-safe?

A2: Yes, the UPE used meets FDA 21 CFR §177.2600 standards for food contact, making it suitable for food processing or beverage handling equipment.

Q3: How do I inspect the seal’s wear status without disassembly?

A3: The transparent white design allows you to visually check the seal lip for cracks, deformation, or debris buildup directly—simply examine the seal through the equipment’s access ports or transparent housings.

Q4: Can Forever Seals provide custom sizes for non-standard equipment?

A4: Absolutely. We offer fully customized seals (size, spring material, and UPE formulation) based on your equipment’s drawings or specifications. Contact our engineering team for a tailored solution.

6. Forever Seals’ Selling Points

- Expertise in Sealing Solutions: With 15+ years of experience in industrial sealing, Forever Seals specializes in designing materials and structures that solve complex sealing challenges.

- Quality Assurance: Every transparent white UPE spring energized seal undergoes strict testing (leakage, wear, and chemical resistance) to meet ISO 9001 quality standards, ensuring consistent performance.

- Customization Capabilities: We work closely with customers to adapt seals to unique operating conditions—from extreme temperatures to specialized fluid compatibility.

- Responsive Support: Our technical team provides pre-sales consultation (application matching) and post-sales support (installation guidance, troubleshooting) to maximize seal lifespan and system efficiency.

把产品详情扩充到300词

生成一个介绍公司的英文视频脚本

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get In Touch With Us

We are committed to meeting the diverse needs of our global customers through innovation and continuous improvement.

Need more information?

If you didn't find what you need, you can send an inquiry through our contact form.

Please fill in the form below.

Quick Links

Products

Contact Us